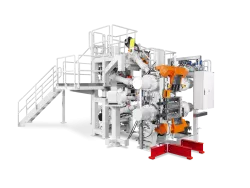

CompoundRework System 1000

For lower costs and high sustainability

Most extrusion processes inevitably involvethe production of a certain amount of recyclable scrap, i.e. residual material that remains in the extruder or in the extrusion head in the event of compound or extrusion tool changes. In order to maximize added value, tire producers strive to recycle this scrap material by returning it to the production process.

- Processing large-volume rubber residues removed from the flow channels as well as start-up scrap

- Compliance with international safety requirements

- Plug-and-play solution

- Investment with rapid payback

Highlights

The CRS 1000 processes large-volume rubber residues removed from the flow channels as well as start-up scrap converting the material into sheets or strips with a thickness of 8 mm. This means that 100% of the residual material can be returned to the production process.

Features

The CRS 1000 is equipped with two (optionally) heated rolls and a hydraulically adjusted roll gap. It can be fed with residual material of various sizes up to a width of one meter.