C-PVC Pipe extrusion

Economic production

When it comes to producing plastic products from C-PVC, many years of experience in extrusion technology are required. KraussMaffei machines are optimally designed in terms of process technology to optimally process all common C-PVC compounds (with an increased chlorine content of 62-69% and a density of 1.50 to 1.55 g/cm³).

- Perfect wear protection

- Economical production with a high degree of automation

- Special screw geometries

- Excellent product quality

High-quality wear protection

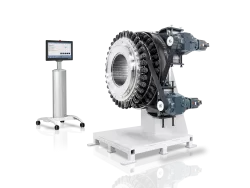

Particularly in C-PVC processing, special attention must be paid to perfect wear protection. All KraussMaffei machines are therefore equipped with fully chrome-plated screws and adapters. We also use fully chrome-plated die sets, molds and hardened calender rolls with bright chrome plating. The screws are molybdenum-welded as standard and operate in a deep-nitrided barrel with high hardness and high hardening depth.

Technical features

KraussMaffei offers you a product range of seven twin-screw extruders with output rates of up to 800 kg/h. Our pipeheads and downstream units can produce pipe in the diameter range from 12 to 500 mm; pipe in the lower diameter range can also be produced using the economical twin-strand process.